Ever since I first assembled a cordless drill1 in our workshop in China, I've been fascinated by the journey each tool takes from raw materials to a trusted companion in your toolbox. Let me walk you through the production process of a cordless drill, a tool that combines precision engineering with practical functionality.

The production process of a cordless drill involves designing components, sourcing quality materials, assembling the motor and gears, integrating the battery pack, and conducting rigorous quality control tests. Each step ensures the drill is efficient, durable, and safe for users.

Understanding this process not only enhances appreciation but also informs better usage and maintenance.

What is a Cordless Drill?

As someone who's spent years crafting these tools, I often get asked: what exactly is a cordless drill?

A cordless drill is a portable, battery-powered tool used for drilling holes and driving screws into various materials like wood, metal, and plastic. It offers mobility without the need for a constant power source, making it versatile for different work environments.

I remember the first time I used one—it felt liberating not being tethered to an outlet. The freedom to move around made projects not just easier but also more enjoyable. The drill's rechargeable battery, usually a [lithium-ion type](What are the advantages of lithium-ion batteries in cordless power tools?)2, powers a motor that turns the drill bit, allowing you to work anywhere.

The Convenience of Mobility

Cordless drills have revolutionized how we approach tasks:

- Flexibility: No cords mean you can work in tight spaces or outdoors without hassle.

- Efficiency: Quick setup and takedown save valuable time.

- Safety: Eliminates tripping hazards associated with cords.

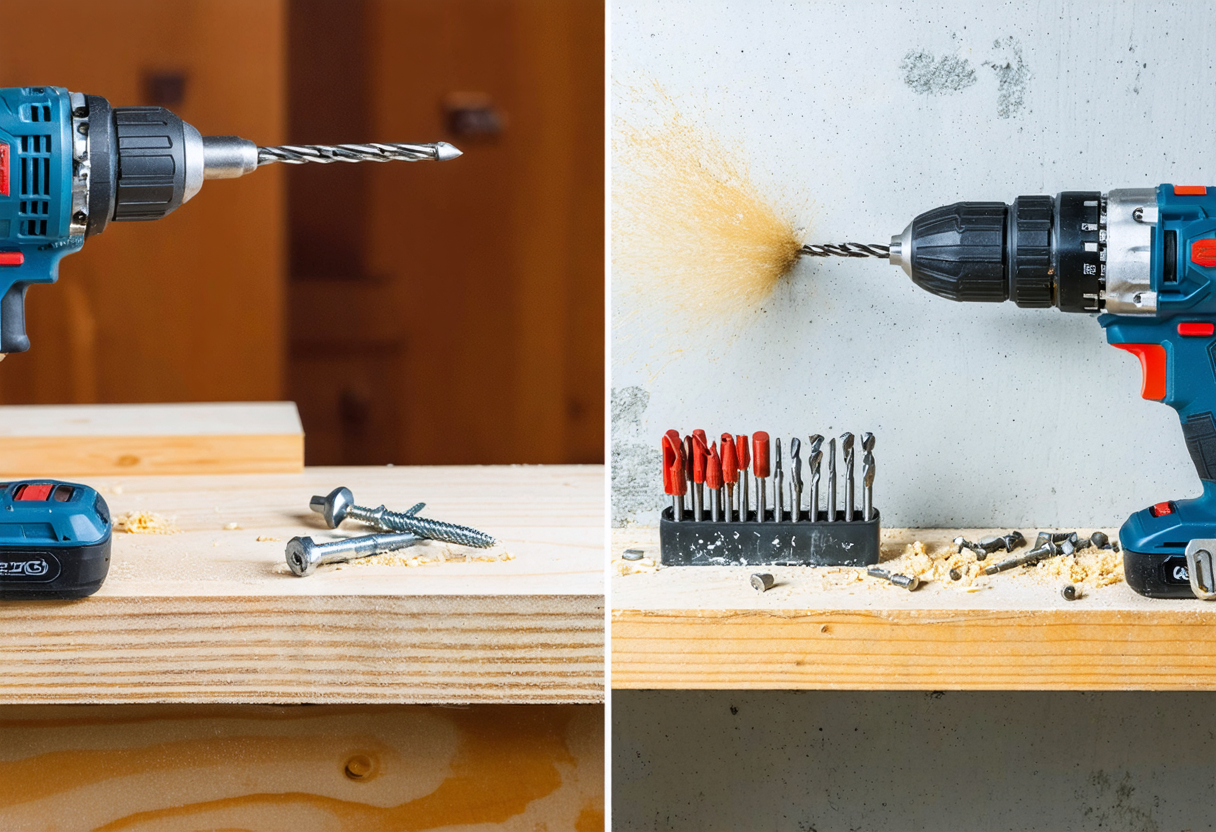

What are the Two Types of Cordless Drills?

Understanding the different types can help you choose the right tool for your needs.

The two main types of cordless drills are drill drivers and hammer drills. Drill drivers are ideal for general drilling and screwdriving, while hammer drills add a hammering action suitable for drilling into harder materials like concrete and masonry.

In our production line, we've crafted both types to meet diverse needs.

Drill Drivers vs. Hammer Drills

- Drill Drivers:

- Perfect for everyday tasks.

- Lightweight and easy to handle.

- Hammer Drills:

- Equipped with a hammering mechanism.

- Ideal for heavy-duty drilling in hard materials.

Choosing between them depends on your specific projects. For instance, when installing shelves at home, a drill driver suffices. But for mounting something on a concrete wall, a hammer drill becomes indispensable.

What are the 3 Main Parts of a Drill?

Knowing your tool inside out can enhance its use and maintenance.

The three main parts of a drill are the motor, the chuck, and the battery pack. The motor powers the drill, the chuck holds the drill bit, and the battery provides the electrical energy for operation.

Each component plays a crucial role:

Breaking Down the Parts

- Motor:

- Converts electrical energy to mechanical motion.

- The heart of the drill.

- Chuck:

- Holds and grips the drill bit.

- Allows for quick bit changes.

- Battery Pack:

- Supplies power.

- Determines how long you can work uninterrupted.

In our assembly process, we pay extra attention to the battery pack. Each cell is individually tested before assembly, and the finished pack is charged to ensure it meets our high-performance standards. If it doesn't, we replace it—no compromises.

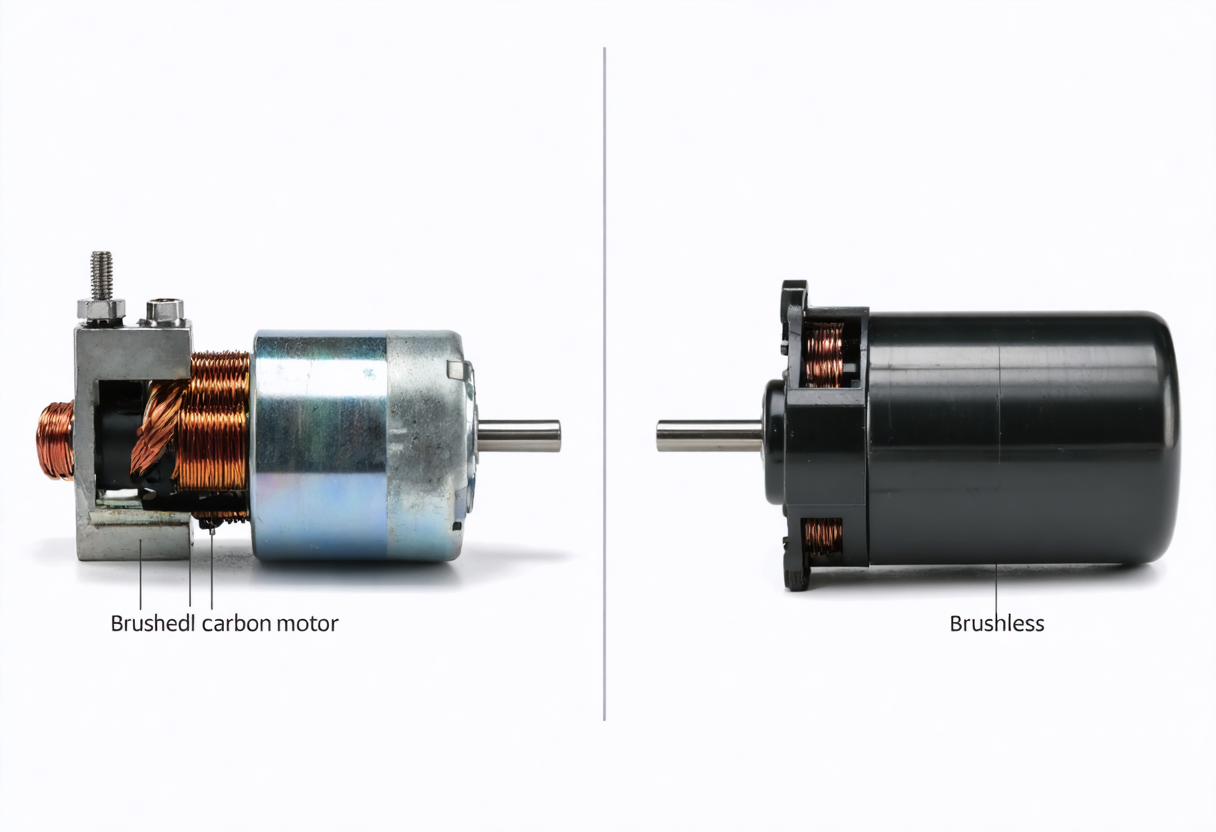

What Kind of Motor is in a Cordless Drill?

The motor type affects both performance and longevity.

Cordless drills commonly use either brushed or brushless DC motors. Brushless motors are more efficient, offer longer battery life, and have reduced maintenance compared to brushed motors, making them a preferred choice in modern cordless drills.

From my experience, switching to brushless motors was a turning point.

Brushed vs. Brushless Motors

- Brushed Motors:

- Have carbon brushes that wear out over time.

- Require more maintenance.

- Brushless Motors:

- No brushes mean less friction and wear.

- More efficient and powerful.

The first time we implemented brushless motors, customers noticed the difference immediately—longer usage times and better overall performance.

How Does a Cordless Power Drill Work?

Understanding its operation can enhance how you use it.

A cordless power drill works by converting electrical energy from the battery into mechanical rotation through its motor. When the trigger is pressed, the motor spins the drill bit, allowing you to drill holes or drive screws into materials.

It's fascinating how squeezing a trigger sets so much in motion.

The Mechanics Behind the Tool

- Trigger Activation:

- Completes an electrical circuit.

- Controls speed and torque.

- Motor Function:

- Drives the gears and chuck.

- Powers the drill bit rotation.

- Variable Settings:

- Adjust speed for different materials.

- Use torque settings to prevent overdriving screws.

This simplicity and efficiency make the cordless drill a staple in toolkits around the world.

How to Maintain a Cordless Drill

Proper care ensures longevity and reliability.

To maintain a cordless drill, regularly clean it after use, keep the battery charged but avoid overcharging, store it in a dry place, and periodically check for wear on parts like the chuck. Proper lubrication of moving parts also helps maintain performance.

From my years in the industry, I've seen well-maintained tools last decades.

Maintenance Tips

- Cleaning:

- Remove dust and debris after each use.

- Pay attention to air vents.

- Battery Care:

- Charge before it’s completely drained.

- Store batteries separately if not used for long periods.

- Regular Inspection:

- Check the chuck for wear.

- Listen for unusual sounds3 that might indicate motor issues.

By taking these simple steps, you not only extend the life of your drill but also ensure it operates safely and efficiently.

Conclusion

Understanding the production process and proper maintenance of cordless drills enhances both appreciation and utility of this indispensable tool. I hope sharing my insights has been helpful. If you're ever in need of quality cordless drills, feel free to reach out at [email protected]. I'm always here to help.

-

This link will help you understand the essential characteristics that make a cordless drill versatile and reliable. ↩

-

This link will highlight why lithium-ion batteries are the preferred choice for cordless drills, focusing on their efficiency and longevity. ↩

-

This link will help identify common issues related to motor or internal component wear based on auditory signs. ↩