Ever stood in front of a motor catalog, scratching your head and wondering why the same tool comes in brushed, brushless, and now... external rotor brushless? Yeah, I’ve been there.

Brushed, brushless, and external rotor motors differ in their internal design, efficiency, and durability. Brushed motors use carbon brushes, which wear out over time. Brushless motors eliminate friction and last longer. External rotor types flip the motor’s structure to deliver higher torque in compact spaces.

If you’re like me, working with cordless tools1 every day, knowing what’s under the hood isn’t just technical talk—it impacts your cost, your customer’s experience2, and your bottom line. So let’s break it down, together.

Which is better, a brushed or a brushless motor?

Not all motors are made equal—and the difference shows up quickly when your tool is under load.

Brushless motors are better than brushed ones in most professional applications. They last longer, run cooler, and deliver more power with less energy loss. Brushed motors, however, are cheaper and easier to repair.

What I learned the hard way

When I first started working with brushed motors, I thought they were a solid, affordable choice. And they are… for a while. But then came the complaints—overheating, downtime, brushes wearing out mid-project. That’s when I knew we had to level up.

Brushless motors changed the game for us. No brush friction. Better battery runtime. Fewer returns. Sure, they cost more upfront—but when you’re shipping to clients across the world, quality isn’t optional. It’s survival.

Here’s a simple breakdown:

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Maintenance | Needs regular upkeep | Low to no maintenance |

| Cost | Lower upfront cost | Higher initial price |

| Lifespan | Shorter | Longer |

| Efficiency | Less efficient | High efficiency |

| Noise | Louder | Quieter |

What are the two types of brushless motors?

Brushless motors come in two main styles, and each has its quirks.

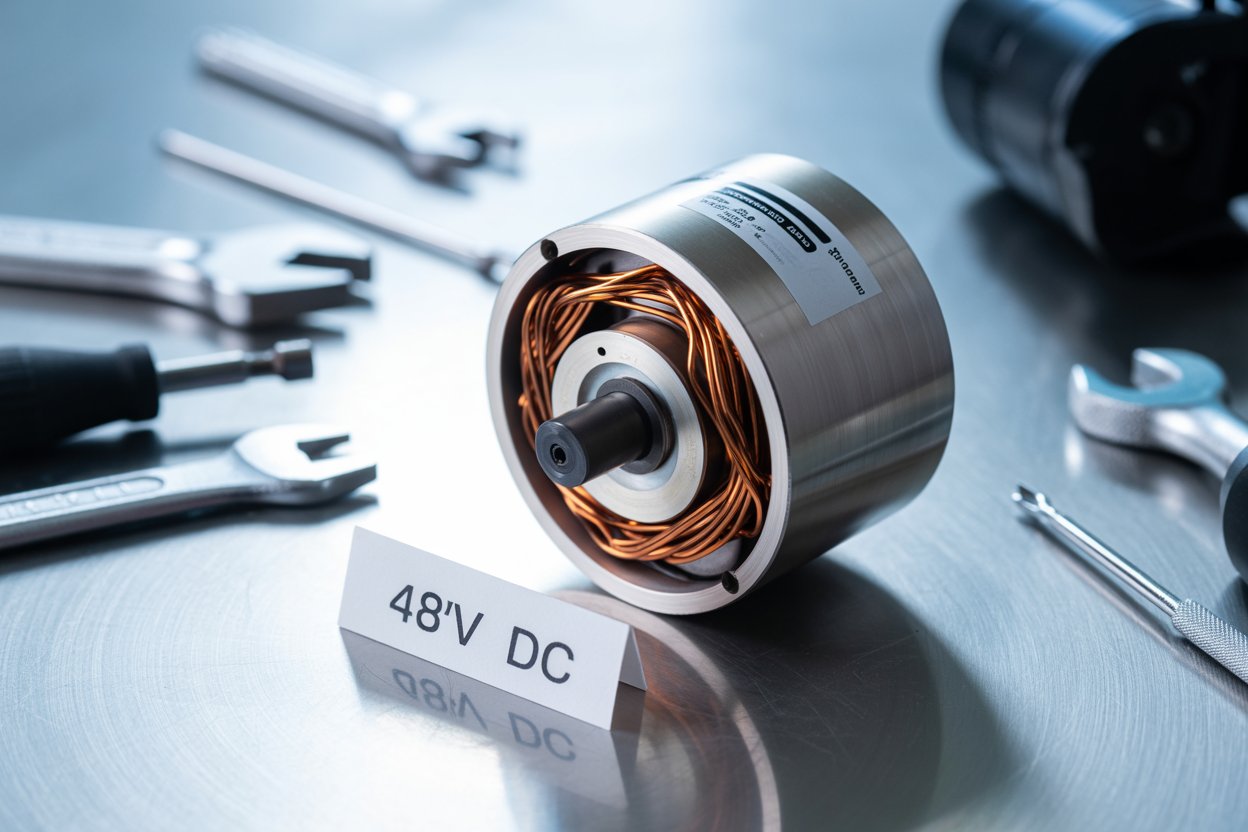

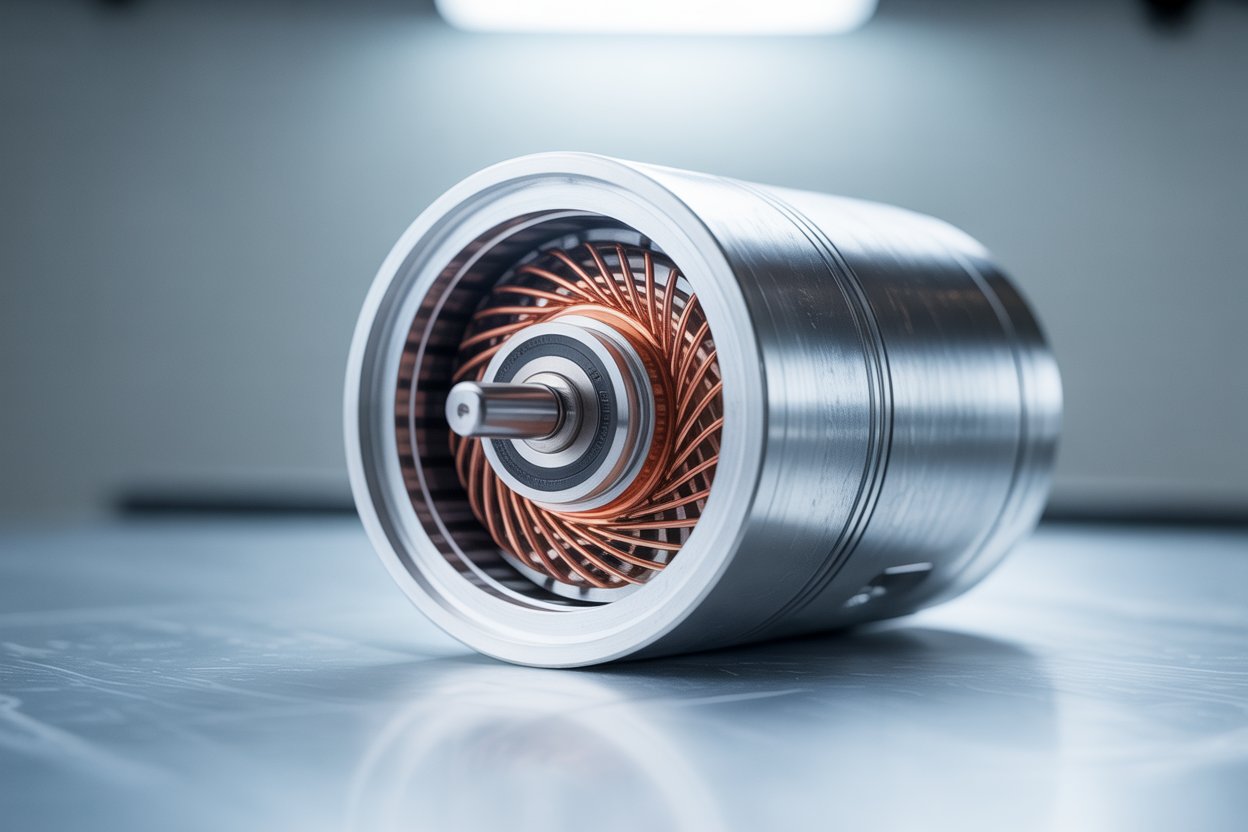

The two types of brushless motors are internal rotor and external rotor. Internal rotor motors have the rotor inside the stator. External rotor motors flip the layout—rotor outside, stator inside—for better torque in compact designs.

Why this matters for cordless tools

Let me give you an example. When we developed our 6-inch chainsaw, we tested both motor styles3. Internal rotor motors3 gave us high RPMs, great for drills. But for saws? Torque is king4. So we went with an external rotor5—it’s like swapping a car engine for one that’s built to pull heavy loads uphill.

And for Deivis—my sharp-eyed buyer friend in Italy—who needs compact tools that pack a punch? External rotors have been a secret weapon.

Here’s how they stack up:

| Motor Type | Positioning | Use Case Example |

|---|---|---|

| Internal Rotor | Rotor inside stator | Cordless drills, blowers |

| External Rotor | Rotor wraps the stator | Chainsaws, fans, saws |

Want to see how we apply brushless motors in real tools? Check out our OEM Brushless Tools case studies for insights.

How do you tell if a motor is brushed or brushless?

This used to confuse me too—until I opened up a few.

A brushed motor has visible brushes or vents where you can see sparks. It often sounds rougher. A brushless motor has a smoother casing and usually runs quieter with no spark or friction noise.

Real-world tip

Here’s how I tell in two seconds flat when I get a sample from a new supplier:

- I listen. Brushed motors crackle slightly; brushless motors hum.

- I look for access panels or vents near the back—brushed motors need brush replacement.

- And if I’m still not sure? I check the controller. Brushless motors need an ESC (electronic speed controller).

Still unsure? Ask for a teardown video from the supplier—or better yet, do one yourself. It’ll save you headaches (and angry buyers) later.

Why external rotor motors are becoming popular?

This trend isn’t just a buzzword. It’s a shift in how we think about performance in compact tools.

External rotor motors are gaining popularity because they offer more torque in a smaller package, which is perfect for cordless tools that need power without the bulk.

My experience with external rotors

A few years ago, we got a request from a French distributor—they wanted a compact pruning saw with high torque. Traditional internal rotors weren’t cutting it (literally). We tried an external rotor setup. Not only did the saw outperform, but it also stayed cooler after heavy use.

Since then, we’ve used external rotor designs in our most demanding models. They’re slightly more complex to manufacture, yes. But the trade-off? A powerful tool that fits in your palm and performs like a beast.

Want to dive deeper? Here’s a technical comparison guide I always share with curious clients.

Conclusion

Understanding motor types isn’t just engineering talk—it helps you pick the right tool for the right job. And in our business, that means better margins, happier customers, and fewer returns.

-

Understanding what cordless tools are and how they operate gives context for why knowing their internal components matters. This benefits readers who may be less familiar with the tools and ensures everyone is on the same page. ↩

-

Helps readers see the direct link between tool performance and business outcomes, reinforcing why it's worth digging into the technical side. ↩

-

Helps readers understand the mechanical differences between the two motor styles and why it matters for tool performance. ↩ ↩

-

Explains why torque is critical in cutting applications like chainsaws, reinforcing the reasoning behind the motor choice. ↩

-

Gives technical depth to the analogy and shows how external rotor motors are optimized for high-torque applications. ↩