I’ve been in the power tool1 industry long enough to know one truth: your battery can make or break your entire product line. If you’re sourcing cordless tools like I am, understanding lithium batteries isn’t optional—it’s the core of your business.

Lithium batteries follow the 80/20 rule: 80% of your performance problems come from 20% of bad battery choices.

Choosing the wrong battery type—even for cost-saving reasons—can lead to poor runtime, overheating, and even product returns. Don’t underestimate this silent profit killer.

So let’s talk about how to choose the right lithium battery. Not just for specs—but for real-world usage, logistics, and the headaches we all try to avoid.

What is the 80 20 rule for lithium batteries?

If you’ve sourced tools before, you know this: one or two weak links ruin the chain.

The 80/20 rule means 20% of your battery choices will cause 80% of your product complaints.

That means even a few poor-quality cells can ruin your reputation, delay your sales cycle, or cause unexpected warranty returns.

Let me give you an example. A few years back, I tested two batches of cordless drills. Both looked identical—but one used low-grade cells to cut costs. After two months in the field, we started hearing complaints about battery swelling and short runtime. That one mistake? It cost us a 50K euro deal with a client in Spain.

Choose your batteries like you choose your partners: not just by price, but by how they perform when the pressure is on.

What’s the lithium battery?

We throw the term around a lot—but what are we really talking about?

A lithium battery is a rechargeable power source that uses lithium ions to store and release energy.

They’re lightweight, charge fast, and have no memory effect, which is why we use them in cordless tools.

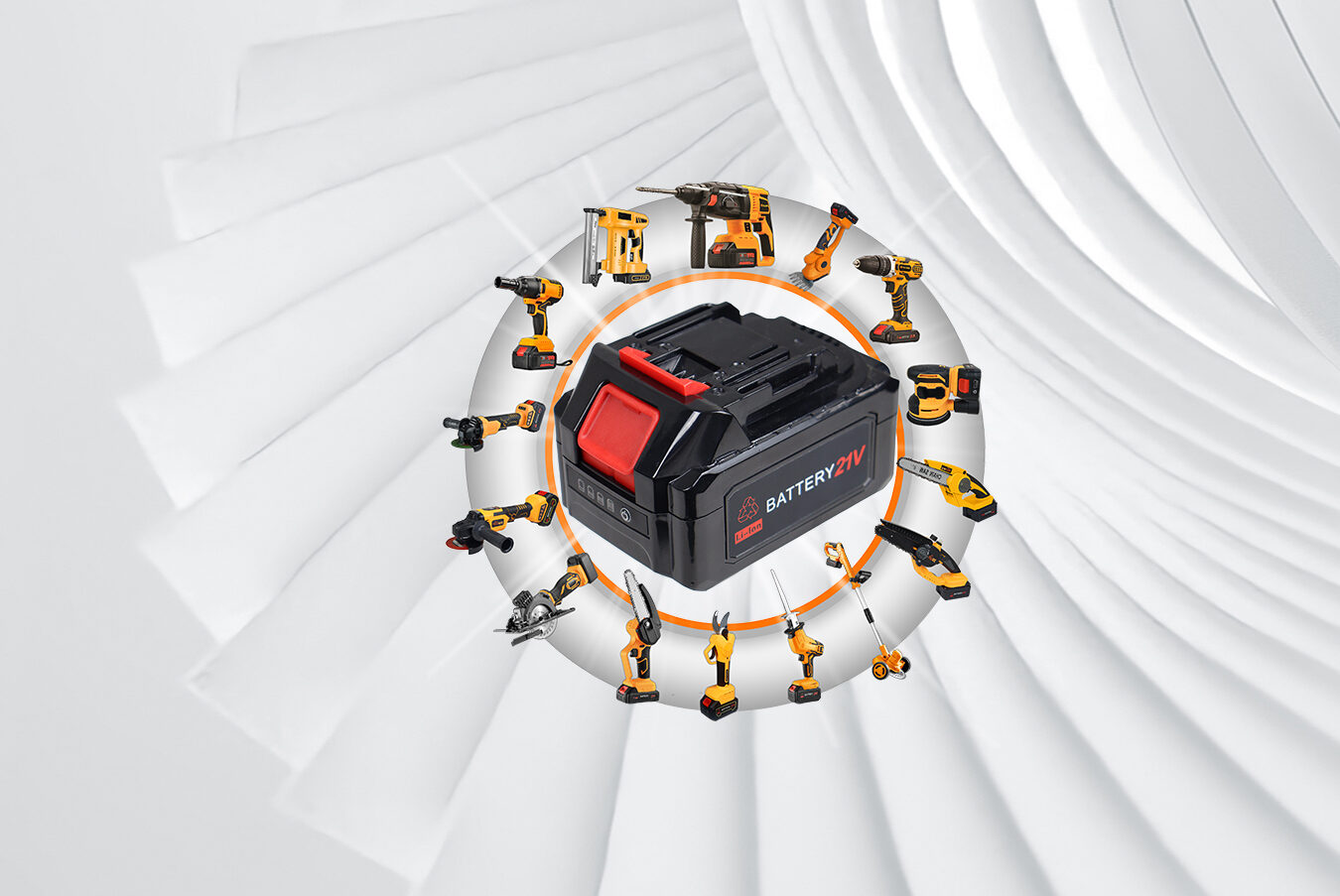

When you hear “21V cordless drill”, it’s not just a number—it’s a system. The cells, the protection board, the assembly method… it all matters. Most suppliers don’t tell you what brand of cell they use. Ask. I always ask: Samsung? LG? Domestic cells? You’d be surprised how often the answer changes once you ask twice.

What’s the function of lithium battery?

If the tool is the body, the lithium battery is the heart.

Its function is to store energy and release it efficiently to power the tool.

The smoother the energy flow, the better your motor performs, especially under load.

When your client presses that trigger, they don’t care about chemistry—they care about torque. But if the battery is cheap or mismatched, you’ll see poor performance under pressure, overheating, or—worse—dead cells mid-task.

Think of it like this: nobody praises the battery when it works perfectly, but it’s always the first thing they blame when something goes wrong.

What’s the type pin of lithium battery 2.0Ah?

Great question—and honestly, one that gets glossed over too often.

Different lithium supplier has its own battery pin, such as bosch, makita, dewalt, milwuakee, Metabo, and so on.

How do I choose a good lithium battery?

You don’t have to be an engineer to spot quality. But you do need to know what questions to ask.

Choose lithium batteries based on cell brand, PCB protection, welding quality, and supplier transparency.

Here’s what I check every time:

- 🔋 Cell Brand: Samsung, LG, or BAK—not random "white label"

- 🧠 BMS/PCB: Overcharge, over-discharge, and temp protection are non-negotiable

- 🔧 Assembly: Clean welding spots, no glue overflow

- 📦 Packaging: Individual cell shrink wrap, anti-vibration foam

If your supplier won’t show you the inside structure, ask yourself: what are they hiding?

Should I charge my lithium battery after every use?

Ah, the golden question from end users—and one that affects returns.

You don’t have to charge it every time, but keeping it between 20–80% prolongs life.

Overcharging and fully draining repeatedly can damage the battery faster.

In my testing room, we tell our partners to store batteries at around 50% charge if they’re not using them for a while. You wouldn’t run your car to empty before refueling every time, right? Same logic applies.

What is the difference between cheap and expensive lithium batteries?

This one stings, especially when a buyer wants to cut costs.

Cheap batteries often use lower-grade cells, unreliable PCBs, and inconsistent assembly.

The result? Shorter lifespan, lower torque output, and a much higher return rate.

Expensive batteries, on the other hand, pay off in the long term. For example, I once tried a low-cost supplier who promised “90% same performance.” Sure—it worked in the first month. But by month three? Half the batch was failing. Replacing them cost me more than the “savings” I made.

Don’t fall for the initial price tag. Look at the total cost of ownership.

How do I know which lithium battery I need?

This depends on what you’re powering—and how often it’s used.

Match your battery based on voltage, amp-hours (Ah), and load requirements of your tool.

Here’s a quick table:

| Tool Type | Suggested Voltage | Capacity (Ah) |

|---|---|---|

| Cordless Drill | 18V–21V | 2.0–4.0Ah |

| Angle Grinder | 21V | 4.0–6.0Ah |

| Pruning Shears | 16V–21V | 2.0–2.5Ah |

| Grease Gun | 21V | 2.0–3.0Ah |

And don’t forget: the fit matters. Always test with your tool housing before committing to bulk.

Conclusion

I’ve learned this the hard way: batteries aren’t just accessories—they’re the foundation of cordless tool performance. Choose wisely, ask the right questions, and don’t let a cheap cell break your brand.

-

from this like you will know the disadvantage of cordless power tools ↩