Struggling to pick a cordless drill that actually fits your needs? You’re not alone.

When buying a cordless drill, focus on voltage, motor type (brushed or brushless), drill size, and intended usage. Matching these specs with your work ensures better results and fewer regrets.

Many of my customers—especially professional buyers—often ask for a drill that’s powerful, durable, and suitable for both light and heavy-duty use. Here's how I help them make the right choice.

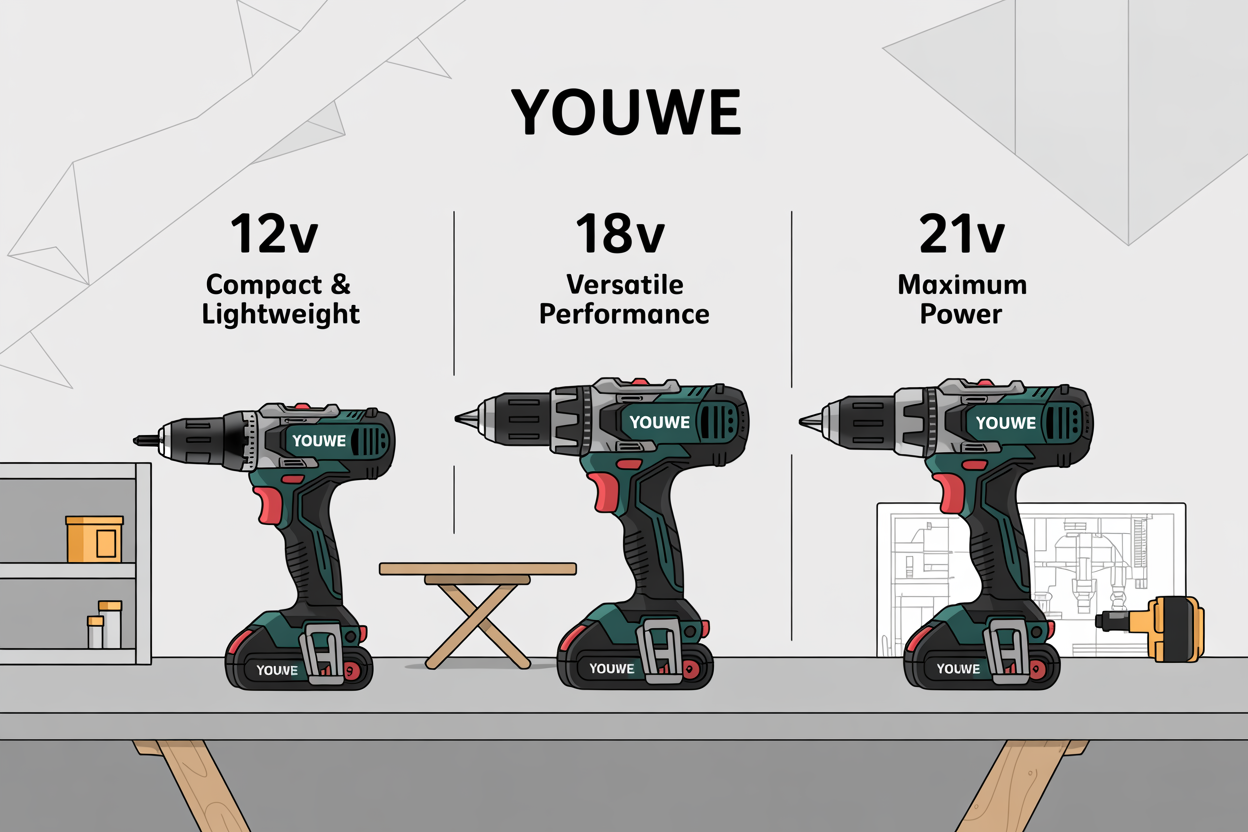

What voltage is best for a cordless drill?

Too low, and it’s underpowered. Too high, and it’s bulky. So what’s the sweet spot?

The best voltage depends on usage: 12V for light-duty tasks, 18V–21V for general and professional use. Most buyers choose 18V or 21V for better performance and flexibility.

How I guide voltage selection for clients

I often get this question at trade shows: “Should I go with 12V[^1] or 21V?” My answer is always the same—it depends on what your customers are doing.

Here’s how voltage impacts performance:

⚡ Voltage vs Power Output Table

| Voltage | Best for | Pros | Cons |

|---|---|---|---|

| 12V | Light-duty, home repairs | Lightweight, affordable | Limited torque and battery life |

| 18V | DIY, light industrial use | Balanced power and size | May struggle with heavy masonry |

| 21V | Pro-level, construction sites | High torque, longer runtime | Heavier, pricier |

I always recommend 21V[^2] for buyers in construction or those supplying demanding customers. It gives them fewer returns, happier clients, and fewer complaints about battery[^3] or torque[^4] issues.

What does "brushless" mean on a drill?

You’ve seen “brushless” on drill listings. But does it really matter?

A brushless drill uses an electronic circuit instead of physical brushes to run the motor. This means more efficiency, less heat, longer tool life, and better battery performance.

Why brushless became the new normal in my product line

Years ago, we offered both brushed and brushless options. But after dealing with repeated issues from brushed motors—overheating, fast wear, inconsistent torque—we gradually shifted most of our 21V line to brushless.

🔧 Brushless vs Brushed Comparison

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Efficiency | Lower | Higher |

| Heat Generation | More | Less |

| Motor Life | Shorter (wears faster) | Longer (no brushes) |

| Cost | Cheaper | Higher upfront cost |

| Battery Life Impact | Drains faster | Uses less energy |

For B2B buyers, brushless might look expensive at first. But in the long run, it's a better value—fewer returns, less downtime, and stronger product reputation.

What size drill is best for home use?

Big drills can be intimidating. Small ones might be underwhelming. What’s the right size?

For home use, a compact cordless drill with a 3/8” (10mm) or 1/2” (13mm) chuck is ideal. These sizes balance drilling capacity with ease of handling.

Why I recommend 10mm or 13mm chuck drills for household customers

I once had a retailer in France order 18V drills with a 1/2” chuck for a DIY promotion. It sold out faster than expected. Why? Because it hit the sweet spot: powerful, but not too heavy.

📏 Chuck Size Reference Table

| Chuck Size | Usage Area | Drill Bit Compatibility | Handling |

|---|---|---|---|

| 1/4” | Light screwing tasks | Small hex bits | Very compact, limited |

| 3/8” | General DIY, furniture | Common HSS bits | Balanced and versatile |

| 1/2” | Heavy-duty drilling (wood/metal) | Larger spade, masonry bits | Slightly heavier |

Most homeowners aren’t drilling concrete walls. They’re fixing shelves, assembling IKEA, or hanging pictures. For that, 3/8” or 1/2” gives them just the right confidence without overkill.

Which type of drill is best for home use?

Too many drill types can overwhelm new buyers. Let's simplify.

A cordless drill driver or cordless hammer drill (18V–21V) is best for home use. Drill drivers handle most household tasks. Hammer drills are better for masonry and brick.

Breaking down the drill types I recommend to distributors

When a buyer asks me, “Which drill should I stock for the home-use section?” I usually offer two SKUs: a drill driver and a hammer drill. That covers 90% of home needs.

🛠 Drill Type Comparison Table

| Drill Type | Description | Ideal For |

|---|---|---|

| Drill Driver | Basic drill + screw-driving function | Furniture, softwood, drywall |

| Hammer Drill | Adds hammering for masonry | Brick, concrete, outdoor walls |

| Impact Driver | High-torque, for screws/fasteners only | Decking, wood framing |

| Rotary Hammer | Heavy-duty masonry drilling (pro-level) | Construction, large renovations |

For home use, the hammer drill wins. It covers all typical jobs and still handles brick if needed. And the 21V cordless version offers plenty of power without needing to plug in.

Conclusion

Choose a drill that matches your needs—not just the price tag. Right features lead to better results and fewer headaches.

[1]:Discover the advantages of 12V drills, especially for light-duty tasks, and how they can be a cost-effective choice.

[2]:Explore this link to understand why 18V–21V drills are preferred for their performance and flexibility in various tasks.

[3]:Explore this link to understand battery types, enhancing your tool's performance and longevity.

[4]:Understanding torque is crucial for selecting the right power tool, ensuring optimal performance for your projects.