Choosing the right manufacturer can feel like navigating a maze. If you’ve ever been stuck between OEMs and ODMs, you’re not alone. Let’s clear up the confusion.

OEM manufacturers create products based on your design, while ODM manufacturers provide ready-to-customize designs. The choice depends on your specific needs, budget, and control preferences.

A few years back, I faced this same dilemma. Let me share what I learned from my journey to make your decision easier.

What is the difference between OEM and ODM batteries?

Batteries power the tools we rely on daily. But have you wondered what separates an OEM battery from an ODM one?

OEM batteries are designed by the buyer, tailored for specific tools, while ODM batteries come from pre-designed molds with customizable features.

Key Features of OEM Batteries

| Feature | OEM Batteries |

|---|---|

| Design Ownership | Fully owned by the buyer |

| Customization | Maximum flexibility |

| Cost | Higher due to unique designs |

Key Features of ODM Batteries

| Feature | ODM Batteries |

|---|---|

| Design Ownership | Shared or owned by the supplier |

| Customization | Limited but efficient |

| Cost | Lower due to shared molds |

Choosing between these options often boils down to your priorities. Need total control over design? OEM1 is the way to go. Prefer cost-effectiveness? ODM2 might be a better fit.

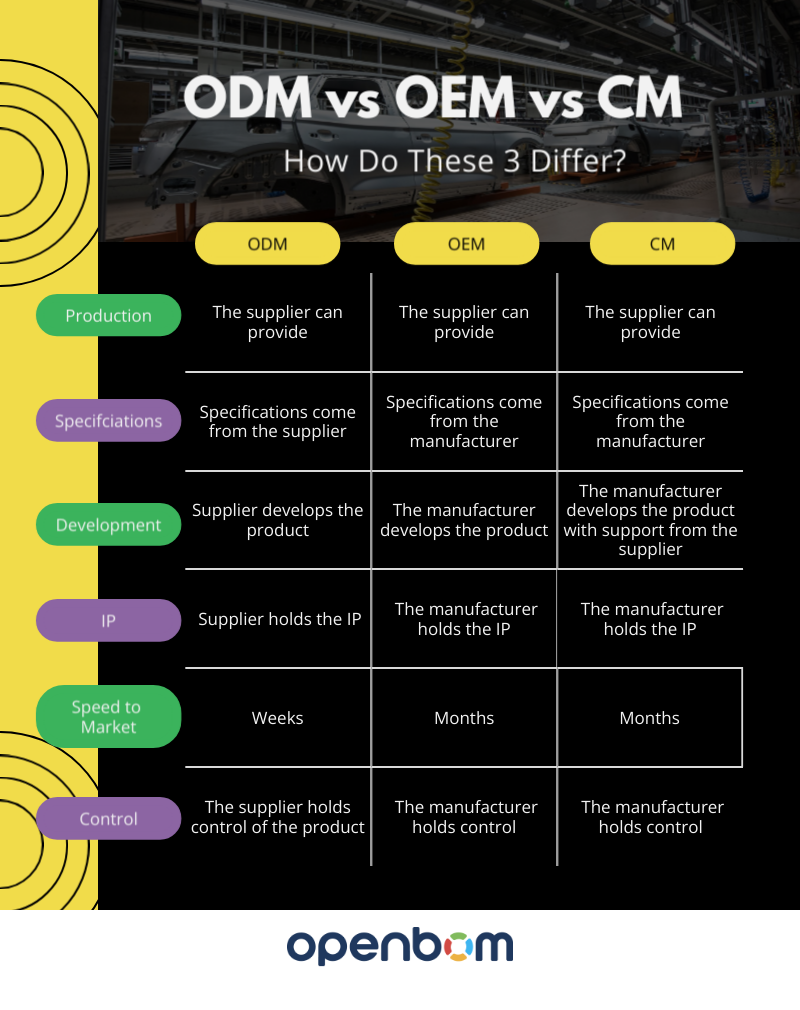

What is the difference between OEM, ODM, and EMS?

Here’s where it gets even trickier. What role does EMS (Electronics Manufacturing Services)3 play in this puzzle?

EMS providers handle the entire production process, from design to logistics. OEM and ODM focus on product design and manufacturing.

Comparing the Three Models

| Aspect | OEM | ODM | EMS |

|---|---|---|---|

| Design | Provided by the buyer | Supplier-designed | Either, depending on scope |

| Manufacturing | Custom and specific | Pre-designed, mass production | Full-service, end-to-end |

| Services | Limited to production | Includes design tweaks | Comprehensive, including logistics |

EMS providers are ideal for businesses wanting an all-in-one solution. However, they may come at a higher cost.

Is it better to buy an OEM battery?

If you’re weighing the pros and cons of OEM batteries, the answer depends on what matters most to you—uniqueness or budget?

OEM batteries are better for unique designs and high-end tools, while ODM batteries offer cost savings with faster production times.

When buying OEM batteries, consider:

- Unique Design Needs: Ideal for niche markets.

- Long-Term Goals: Higher upfront cost but better brand positioning.

- Quality Control: You have full oversight.

On the flip side, ODM batteries suit:

- Cost-Conscious Buyers: Savings on design and R&D.

- Time-Sensitive Projects: Faster production cycles.

- Small to Medium Enterprises: A practical choice for scaling.

What is the difference between OEM and non-OEM?

You’ve probably come across “non-OEM” products. What makes them different from genuine OEM ones?

Non-OEM products are third-party-made and not affiliated with the original brand, unlike OEM products, which are built to brand specifications.

Why It Matters

| Aspect | OEM | Non-OEM |

|---|---|---|

| Quality | Guaranteed to fit specs | May vary |

| Warranty | Typically included | Rarely offered |

| Cost | Higher | Lower |

While non-OEM products might seem appealing due to lower costs, they often lack the reliability of OEM parts.

Conclusion

OEM and ODM serve different needs. The right choice depends on your goals, whether it’s customization or cost-efficiency.

-

Understand how OEM offers businesses complete control over the design process, crucial for creating custom products. ↩

-

Learn why ODM is considered cost-effective and how it contrasts with OEM in terms of design flexibility. ↩

-

Discover how EMS fits into the broader manufacturing landscape and its role in production and supply chain management. ↩