Ever found yourself scratching your head over which power tool to pick? Trust me, you're not alone. I've spent countless hours mulling over the pros and cons, especially when it comes to brushless power tools.

Brushless power tools are known for their efficiency and durability, but they come with disadvantages like higher costs, complex repairs, and reliance on sophisticated electronics. These factors can make them less accessible for some users, especially when considering maintenance and upfront investment.

But let's dig a little deeper, shall we?

What are the advantages of brushless tools?

The first time I used a brushless tool, it felt like unlocking a new level of productivity.

Brushless tools offer increased efficiency, longer battery life, and greater power output compared to brushed counterparts. They run cooler and require less maintenance, making them ideal for heavy-duty tasks and prolonged use.

The Efficiency Game Changer

Brushless technology eliminates friction caused by brushes, reducing energy loss. Imagine driving a car that sips fuel—it's kind of like that. You're getting more work done without draining the battery as quickly.

- Longer Lifespan: Fewer moving parts mean less wear and tear.

- Higher Torque: More power for those tough jobs.

- Low Maintenance: Less time fiddling, more time building.

What is a brushless motor?

If you're wondering what's under the hood, let's unwrap it together.

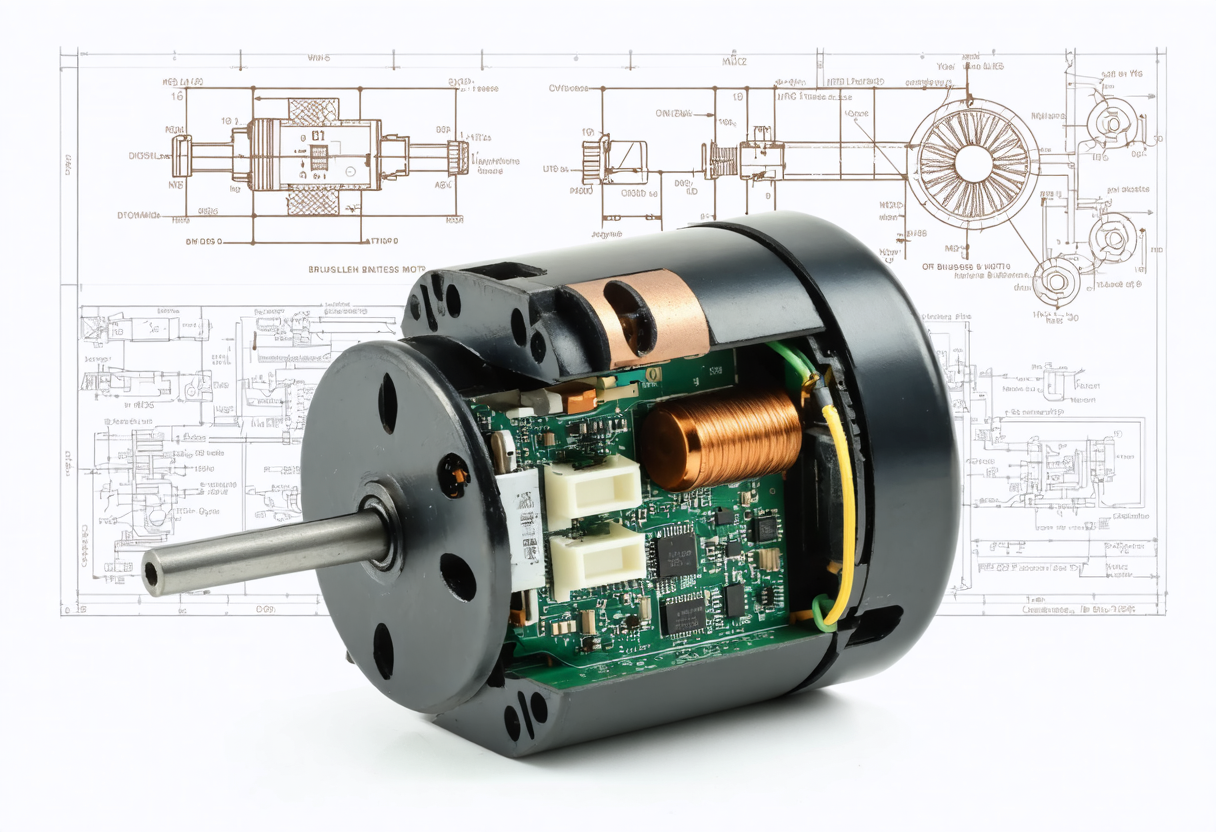

A brushless motor operates using electronic commutation instead of traditional brushes. This design increases efficiency, reduces heat, and extends the motor's lifespan, making it a superior choice for modern power tools.

How Does It Work?

Think of it like a dance between magnets and electronics. The motor uses permanent magnets and smart circuitry to create motion without physical contact. No brushes rubbing means less friction and more smooth sailing.

| Component | Function |

|---|---|

| Permanent Magnets | Create a magnetic field |

| Stator Windings | Conduct electricity |

| Electronic Controller | Manages motor function |

What are the downsides of a brushless motor?

Now, every rose has its thorns, and brushless motors are no exception.

The downsides include a higher initial cost, complexity in repairs, and dependency on electronic components that can fail. Repairs often require specialized knowledge, making DIY fixes challenging and sometimes expensive.

The Repair Dilemma

I once had a brushless drill1 that stopped working mid-project. Turns out, fixing it wasn't as simple as replacing a part—it needed expert attention. The electronics that make it efficient also make it tricky when things go south.

- Higher Costs: Upfront and for repairs.

- Complexity: Not ideal for quick fixes.

- Availability: Replacement parts can be scarce.

What are the applications of brushless motors?

So, where do these motors really shine?

Brushless motors are widely used in applications requiring high efficiency and precision, such as cordless power tools, drones, electric vehicles, and industrial machinery. Their reliability and performance make them a top choice in advanced technology sectors.

Beyond Just Tools

From powering your cordless drill to propelling electric cars, brushless motors are the unsung heroes. They're also in your favorite gadgets and even in the equipment used by professionals in various industries.

- Drones: For smoother flights.

- Electric Bikes: For efficient commuting.

- Industrial Equipment: For reliable performance.

Conclusion

Choosing between brushless and brushed2 power tools boils down to your specific needs and budget. While brushless tools offer remarkable benefits, they're not without their drawbacks. Weighing these factors can help you make an informed decision that'll keep your projects running smoothly.